How can safety audit software help with 5S audits?

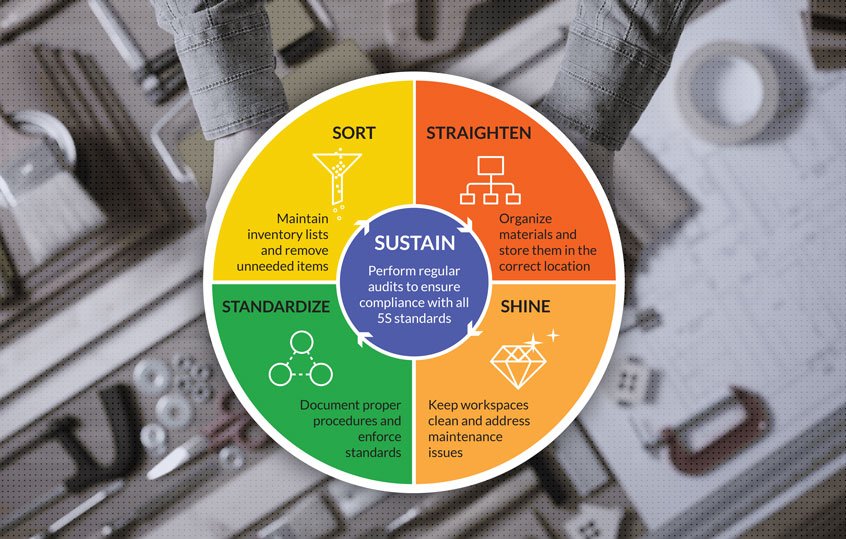

If you work in manufacturing, you’re probably familiar with the concept of 5S audits. If you aren’t, they’re simple, routine audits that check criteria for 5 workplace expectations: Sort, Straighten, Shine, Standardize, and Sustain. A sixth expectation, Safety, is so important that it usually has its own category. The 5S (or 6S) method is designed to help manufacturers improve processes by scoring locations on criteria in each category and correcting issues.

5S is a great way to track the successes and failures of your current practices. The only question is, what’s the best way to conduct these audits? While traditional methods like paper and spreadsheet forms can get the job done, they’re not the fastest or most effective means available.

To make your 5S audits as simple and routine as they’re designed to be, safety audit software can help you create easy-to-use mobile forms.

Just look for these built-in features:

1. In-Form Information

Embed reference information into each section so your auditors understand exactly what they’re looking for and how to score every criteria.

2. Photo Validation

Take photos while inside the app to gather evidence and verify audit data. After they’re taken, use markup features to draw on images and highlight violations or other important details.

3. Scoring

Post-submission scoring will show your team exactly how successful they were at meeting your expected 5S standards and highlight areas in need of improvement.

4. Remediation Plans

Automatically generate remediation plans after audits are completed based on scores in each of the 5S sections. Plans can include a full report or individual tasks with due dates and criticality levels.

5. Workflow

Quickly respond to problems with automated workflows that pass audit results along to the right people, assign follow-up tasks, and send out alerts to responsible parties.

Interested in learning how Form.com can help you tackle your 5S initiative? Contact us today!