What are Business Processes for Operational Excellence?

No matter what industry you’re in, from food service and hospitality to facilities and manufacturing, following operational standards is critical in delivering safety, consistency, and satisfaction. It’s also estimated that ensuring compliance across every inspection and audit saves businesses an average of $2.86 million each year.

Ensuring standard processes is a key component of maintaining operational excellence, which can be viewed as the continuous improvement and execution of your business strategy and goals. Operational excellence might sound simple, but it can be complex in practice—especially if you’re dealing with multiple facilities, stores, or locations. One recent study found that even though 69% of companies had documented, repeatable processes, only 4% of them monitored and controlled them.

The larger your business, the more difficult it can become to understand and act on changing conditions at multiple locations, with many organizations using incompatible systems, convoluted spreadsheets, and, in some cases, a scrap piece of paper. Using these disparate methods and outdated techniques can cause inconsistencies and lost time at best, and at worst, lost profits and safety concerns.

Instead of wrangling together data silos and paper-based processes, businesses can consolidate their efforts and turn their attention to achieving operational excellence through digitized and consistent processes. While there are many methodologies associated with operational excellence—Six Sigma, Hoshin Kanri, and The Shingo Model—it all comes down to building consistent and reliable processes and continuously improving them through regular monitoring. Still sounding complicated? We’ve broken operational excellence down into seven key principles and achievable steps to help you and your team get started.

1. Establish a Baseline for Employee and Process Performance

Operational excellence isn’t something organizations achieve overnight; it requires long-term strategic planning that takes into consideration every element of the organization and its processes. To excel in operational excellence, teams must begin with the end in mind—establishing a comprehensive picture for achieving end-to-end flow.

Because of the big-picture nature of operational excellence, companies can’t expect to immediately understand the capabilities of their processes, locations, and people. It often takes time to establish a baseline, and it can be nearly impossible if teams are chasing numbers from various systems, spreadsheets, and paper-based forms.

By beginning with the end in mind, teams can focus on specific KPIs while consolidating processes into lean, determinable (and ideally digital) flows. Goals and objectives should follow the SMART principle (Specific, Measurable, Achievable, Relevant, and Time-bound) and be designed to ensure optimum success from every part of the organization.

Instead of a goal like “Increase customer satisfaction,” try “Increase this specific location’s customer satisfaction survey score by 10% by the end of the year.”

2. Move Data Collection & Operations to One Mobile System

In today’s world of immediacy and digitization, there are endless tools and software to help teams achieve goals. But with so many options available, it can sometimes harm efficiency rather than facilitate it. Imagine that you evaluate brand sentiment and guest experiences with a mobile app designed for your industry. You also use a traditional spreadsheet to collect quality control data and use paper forms for safety evaluations. Meanwhile, all your sales, order management, and supplier audits are isolated on an entirely separate system. Why collect all of this data if none of it works together?

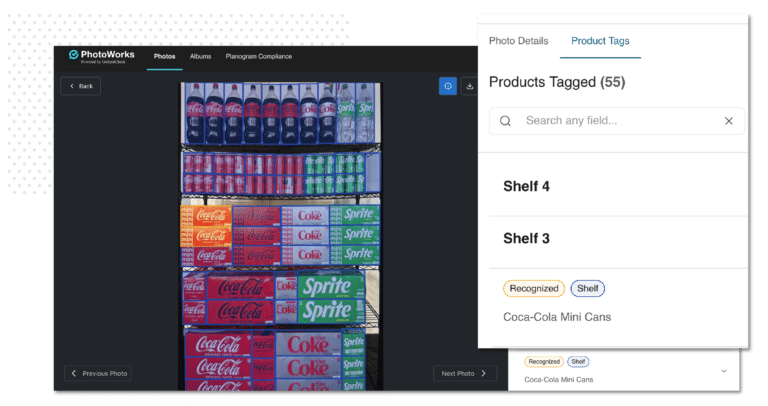

With a flexible enterprise data solution, you can make all this information work together in a single system. By moving audits, inspections, daily checklists, and SOPs to mobile, teams can create repeatable processes that empower frontline employees and further operational excellence. In addition to consistency and ease, consolidating and digitizing data gives teams the ability to compare, analyze, and understand data across multiple locations, times, and users. Having access to insights in one place also simplifies the process of making data-driven decisions—instead of micromanaging day-to-day tasks, operational leads can focus on big-picture goals, planning growth, and continuous improvement.

Operational Excellence Examples

Major League Baseball team, the Detroit Tigers, discovered the value of single-platform data collection and management when they made the switch to FORM OpX. Instead of carrying out pre- and post-game checklists across different systems of pen-and-paper or email, they now centralize tasks and inspections into one app—even utilizing photo reports to ensure visual confirmation. With so much time saved, The Tigers have more time to focus on creating that beloved baseball experience.

3. Leverage Data Analytics to Make Informed Decisions

Data analytics can show organizations the patterns and insights that emerge from information collected, and help teams draw conclusions and make decisions. Becoming data-driven has been a common objective for many organizations in recent years. (In fact, thanks to Oakland Athletics and the “Moneyball” story, Major League Baseball now famously uses data analytics to evaluate players). However, many companies are still slow to adopt this data-driven approach, with 53% of C-Level Executives admitting that they don’t treat data as a business asset.

However, when organizations treat data as a tool, they can be one step closer to achieving operational excellence. With the right system in place, teams can get a closer look at real-time data and metrics and use these in the decision-making process. By looking at data from your locations and facilities from last week compared to last month and last year, you can identify trends and areas of opportunities.

You can even compare data captured from one particular location to locations all over the world to uncover the cause behind downward trends to make improvements or take preventative actions. With FORM’s custom reports and dashboards, you can create flexible cross-sections of your data that break the numbers down into bite-sized chunks. You can easily share these with your contacts and include charts, graphs, and data visualizations to highlight key areas of interest.

Operational Excellence Examples

Fast food chain Wendy’s uses FORM OpX to modernize the way their restaurants collect and act on operational data, creating data-driven workflows used to promote system-wide operational excellence, continuous improvement, and customer satisfaction.

4. Get Instant Insight into Operational Execution (And Fix it in Real-Time)

Even if organizations are using data in the decision-making process, if they don’t have a digital data management system in place, it could take weeks, or even months, to gather, process, and analyze certain data. By using a mobile solution, teams can get insight into operational execution, trends, and data almost instantly, and become agile to adjust and fix issues in near real-time.

FORM OpX allows teams to create powerful workflows that connect people, processes, and reports across multiple locations. The app also delivers automated alerts and escalation paths so that any issues are rapidly brought to the appropriate team members, making resolution efficient and effective. When using FORM OpX, frontline employees no longer have to wait for top-down approval—decisions to resolve issues or improve resolutions can be on-time, all of the time.

5. Prioritize Employee Advocacy and Engagement

If there’s one thing to remember about achieving operational excellence, it’s that your team members are the ones who will be putting your strategy to work. Frontline employees are the individuals who are out on the floor handling day-to-day operations, and the ones who are most likely to spot inefficiencies and areas of process improvement when doing daily audits and checklists. To achieve your operational excellence goals, you’ll need to gather input from these team members on how your processes are currently working, and how they could be improved. Instead of taking a top-down or bottom-up approach, it can be valuable to encourage a positive organizational culture by gaining insights from directors, managers, and frontline workers equally. Everyone can play a role in making your company better.

Furthermore, by fostering a culture of continuous improvement and learning, organizations can empower their employees to work toward excellence goals. One report suggested that when team members feel valued, inspired, and highly engaged, they can be up to 125% more productive than other employees. When every member of the company is aligned with the same mission of continuous improvement, decisions can be made and implemented more quickly.

Operational Excellence Examples

Sunrise Senior Living leverages FORM OpX’s mobile app to manage hundreds of operational, health, and safety SOPs, including COVID protocols throughout their communities.

6. Promote Ongoing Communication and Feedback

Regardless of industry, poor communication can be damaging to an organization. It can result in anything from the wrong shipment of food getting sent to a restaurant to a workplace safety accident.

And when hundreds of locations are involved, any miscommunication can have a major impact. Even worse, if a company isn’t regularly auditing, management may not realize the issue until it’s too late.

Maintaining clear communication can prevent major issues while ensuring that everyone is well-connected (especially important in today’s remote world) and on the same page. According to a report by McKinsey, well-connected teams see a productivity increase of 20-25%.

Mobile communication solutions can keep everyone on the same page automatically. FieldConnector, FORM’s field communication app, allows teams to communicate instantly and effectively from wherever they are. Frontline workers can share updates with peers, executives, and even teams in other locations. When SOPs or safety regulations change, managers won’t need to worry about sending out a memo or addendum. With read receipt verification, channels, and filters, FieldConnector ensures the right communication is going to the right person at the right time.

7. Measure the Success of Your Operational Excellence Program

Implementing an operational excellence program requires extensive resources—from strategizing, implementing, and training team members. How can teams ensure that their operational excellence program is worth the time and effort?

Remember the benchmarks we established in Step One? After implementing your operational excellence strategies and new business processes, it’s time to return to your original metrics and KPIs. Questions to ask yourself about your business outcomes may include:

- How much value has been captured over the last 12 months from driving operational improvements?

- Has workplace culture and employee engagement increased at all? Has the employee turnover rate changed?

- What is our retention or rejection rate of implemented improvements/methods?

- Have we experienced fewer injuries and loss of time?

- Have we received any feedback on customer experience?

- Have we increased our profit margins and bottom line?

When evaluating these benchmarks, however, don’t forget to take into consideration both internal and external factors.

- External Benchmark: Are you meeting or exceeding the growth rate of your competitors? Can you keep it up long enough to gain a competitive advantage?

- Internal Benchmark: How much value has been captured from driving operational improvements?

The Next Steps in Maintaining Your Operational Excellence Strategy

Achieving operational excellence may sound complex and unattainable, but with the right methodology, digital management systems, and mindset, it can be within reach for your organization. McKinsey found that organizations that took a “rigorous” approach to operational excellence and included key elements like effective communication, active leadership, empowered staff, and an environment of continuous improvement, found success with their transformation 79% of the time.

Of course, operational excellence is a constantly moving target. Teams need to continuously maintain and revise their processes as their company evolves, always aiming to work even faster, smarter, and more efficiently than before. The key to staying ahead of trends is to always be measuring, analyzing, and communicating data as clearly and quickly as possible.

With FORM, teams can do this all in one platform. Our mobile software combines task management and workflows with communication, photo reporting, and insights—allowing teams to easily and efficiently focus on operational excellence.

Ready to learn more about how FORM can help you drive efficiency and results, all on mobile? Get in touch with a solutions expert and see how our mobile audit management software makes it easy to get reliable data from anywhere in the world.